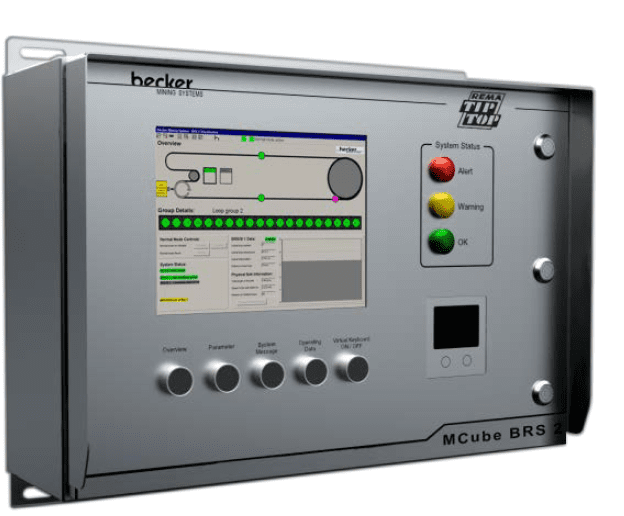

Becker Mining Belt Rip Detection System BRS 2

Reliable Rip Detection for Enhanced Belt Safety

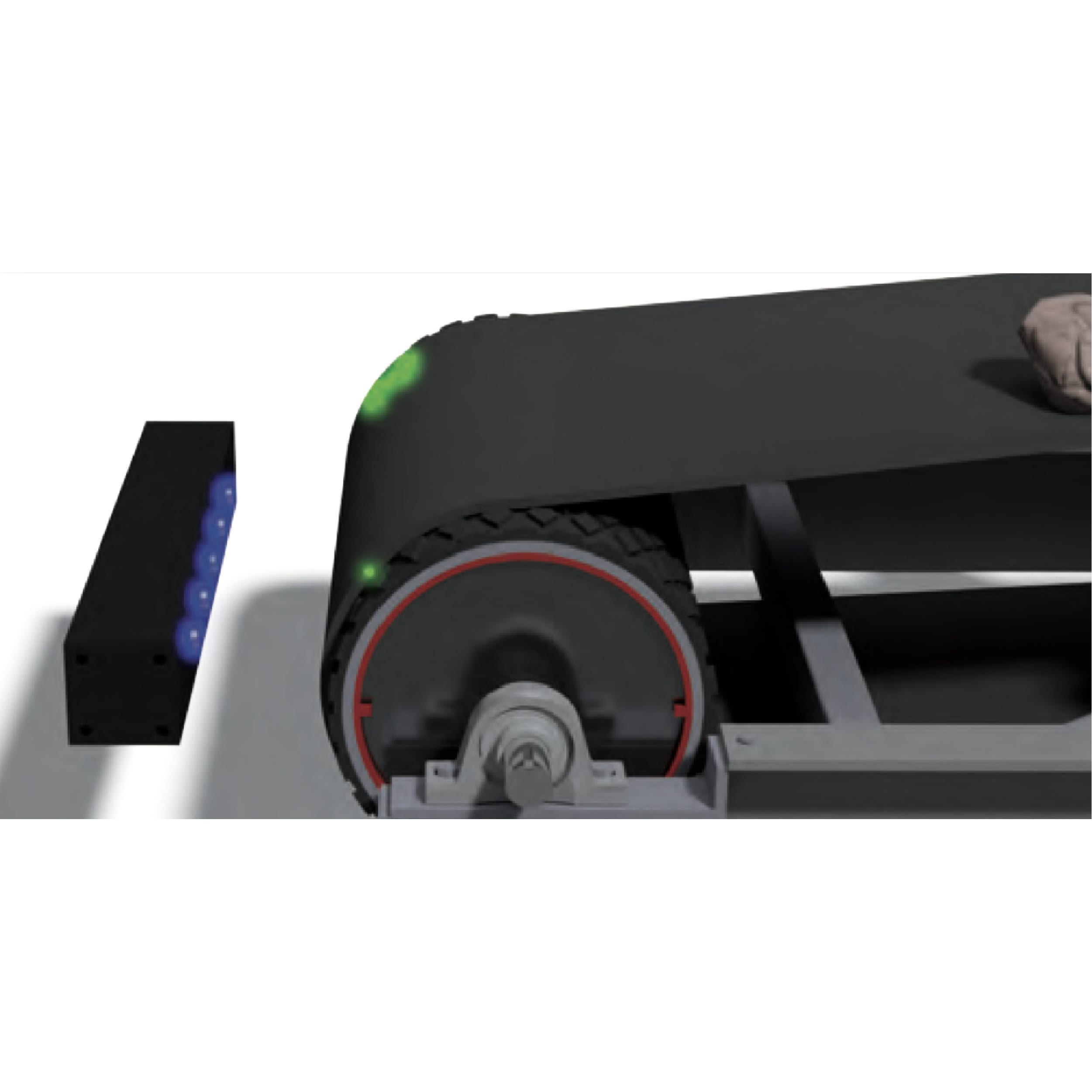

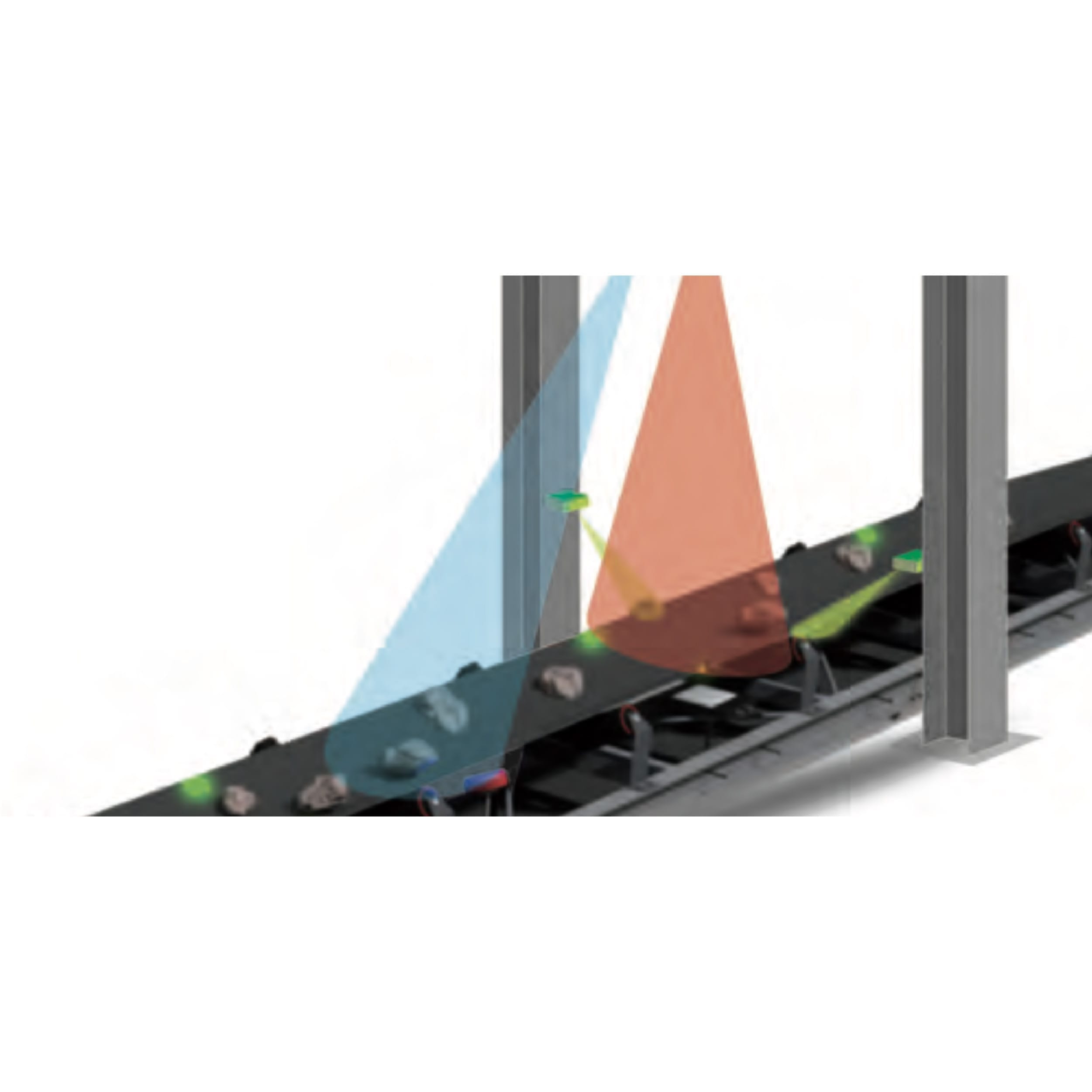

The Becker Mining Belt Rip Detection System (BRS-2) is designed to significantly improve the productivity and safety of conveyor belt operations. Using advanced inductive loop technology, the BRS-2 system detects rips and tears in conveyor belts in real time, enabling immediate response to prevent further damage and reduce downtime. Whether monitoring steel cord or fibre belts, the BRS-2 offers reliable and accurate rip detection, making it an essential tool for maintaining operational efficiency in demanding environments.

INTERNATIONAL

INTERNATIONAL