Achieving Operational Continuity: The Impact of AI-Powered Rip Detection

REMA TIP TOP was approached by a leading gold miner in the Kalgoorlie region with a critical challenge: frequent unplanned downtime in their plant facility caused by belt rips. This downtime not only disrupted their operations but also resulted in significant financial losses and efficiency drops.

To address this issue, REMA TIP TOP proposed the implementation of an advanced belt rip detection technology. This solution aimed to proactively monitor the integrity of conveyor belts and enhance operational efficiency.

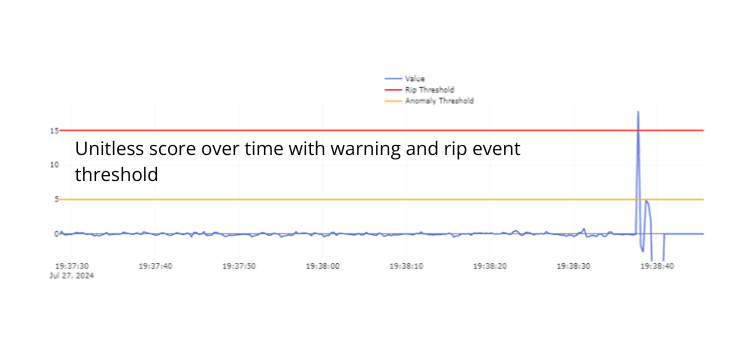

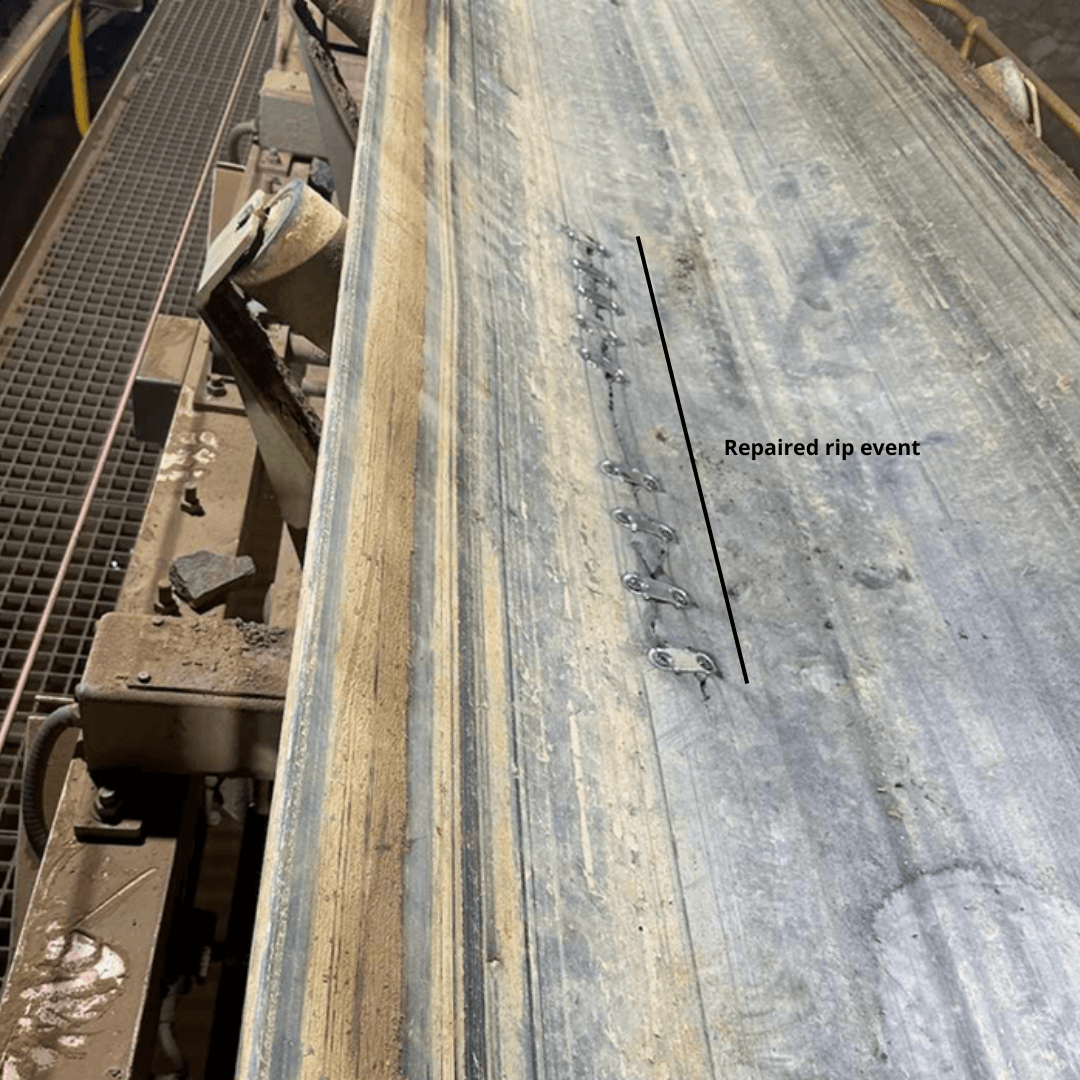

Highlight: On the 27th of July, the Loopless Rip Detection system successfully detected a belt rip and halted the conveyor within 1.5 meters, preventing significant damage and operational disruption. This case study details the challenges faced, the innovative solutions implemented, and the measurable outcomes of this critical event.

Project Background

Belt rips are a significant issue in conveyor belt systems, causing unplanned downtime that can bring an entire plant to a standstill. Statistics indicate that over 90% of all longitudinal rips occur in the loading area, making it a critical point of failure. Traditional condition monitoring solutions, such as the ‘Fishing Line’ method and Rip Detection Systems with sensor loops, have been employed to address these issues. However, they come with inherent limitations:

Fishing Line Method:

- Uses a piece of string beneath the conveyor’s carry side, attached to an electrical switch.

- Activates if material penetrates the belt and touches the string.

Rip Detection Systems with Sensor Loops:

- Utilise sensor loops embedded in the conveyor belt at regular intervals.

- Require a minimum cover thickness of 6mm.

- Sensor loops have a finite lifetime and may work intermittently as they near the end of their life.

- Susceptible to damage, causing false alarms.

Recognising these limitations, the customer sought a more reliable and efficient solution. They approached REMA TIP TOP for a cutting-edge technology that would not only detect belt rips but also mitigate unplanned downtime effectively.

Solution

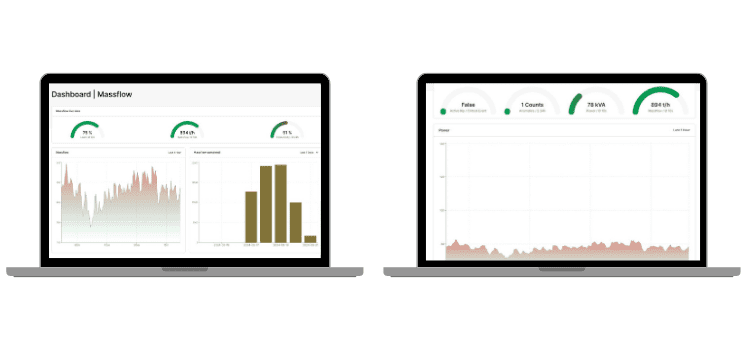

REMA TIP TOP proposed the implementation of a Loopless Rip Detection system. This innovative solution leverages intelligent mathematical algorithms (AI-based) to detect anomalies in motor current and voltage, eliminating the need for sensor loops or other sensing elements inside the conveyor belt. Key features of this system include:

- No Sensor Loops: Unlike traditional systems, it requires no sensor loops, reducing the risk of damage and false alarms.

- AI-Based Detection: Utilises intelligent algorithms to accurately detect anomalies.

- Ethernet Accessibility: Accessible via Ethernet for multiple users.

- Readily Available Data: Uses existing input data from the conveyor system.

- Integration: Can be integrated into almost any conveyor system.

- Emergency Response: Output relays can connect to PLC to stop the belt in emergencies.

- Extendable Add-Ons: Includes features like Drive Monitoring, Massflow Calculation, Electrical Network Analysis, and Maintenance Support.

By implementing this advanced Loopless Rip Detection system, REMA TIP TOP aimed to provide the customer with a robust solution that ensures operational continuity and reduces unplanned downtime.

Challenges Faced

In the mining industry, conveyor systems are critical for the efficient transport of materials. However, these systems are prone to frequent belt rips, which can cause significant operational disruptions. For the customer, the primary challenges included:

Frequent Belt Rips:

- Over 90% of belt rips occurred in the loading area, leading to unplanned downtime and operational inefficiencies.

Operational Disruptions:

- Belt rips often resulted in halting operations, sometimes bringing the entire plant to a standstill.

- The financial impact of these disruptions was substantial, including repair costs and lost productivity.

Limitations of Traditional Solutions: Traditional methods such as the ‘Fishing Line’ technique and sensor loop systems had several drawbacks:

- Susceptibility to damage and false alarms.

- Finite sensor lifetimes, requiring regular maintenance and replacements.

- Requirement for a minimum belt cover thickness, limiting their applicability.

Implementation:

To address these challenges, REMA TIP TOP introduced an advanced Loopless Rip Detection system tailored for the mining industry. The implementation process included:

Assessment and Customisation:

- Detailed assessment of the client’s existing conveyor system to customise the solution.

- Integration of AI-based algorithms to detect anomalies in motor current and voltage without the need for sensor loops.

Installation and Integration:

- Seamless installation of the Loopless Rip Detection system.

- Integration with the client’s existing conveyor systems, ensuring compatibility and minimal disruption during implementation.

Real-Time Monitoring and Alerts:

- Implementation of real-time monitoring capabilities, accessible via Ethernet for multiple users.

- Configuration of output relays to connect to PLCs for emergency stoppages, enhancing safety measures.

Extended Functionalities:

- Addition of Drive Monitoring, Massflow Calculation, Electrical Network Analysis, and Maintenance Support.

- These add-ons provided comprehensive insights and support for the client’s operational needs.

Results and Outcomes:

The deployment of the Loopless Rip Detection system resulted in significant improvements for the customer:

Highlight: Successful Rip Event Detection:

The Loopless Rip Detection system was installed on the 18th of June. On the 20th of June, the system successfully detected its first belt rip, resulting in a rip length of only around a metre. This rapid detection and response significantly minimised potential damage, showcasing the system’s effectiveness in real-world conditions.

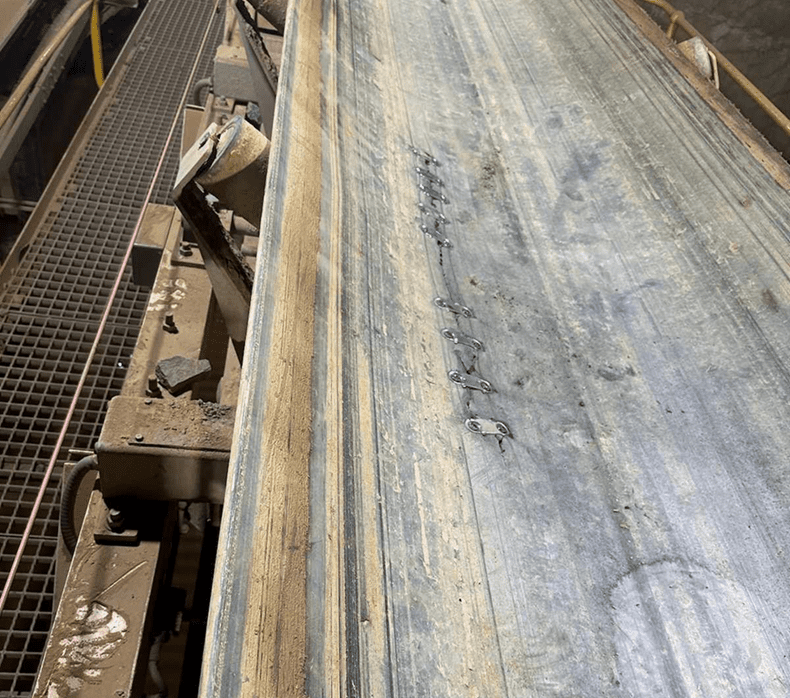

The below images are from the second detected rip event on July 27th.

Reduction in Downtime:

- A notable decrease in unplanned downtime, ensuring continuous operations.

- Enhanced productivity and efficiency, leading to substantial cost savings.

Improved Reliability:

- The AI-based detection system provided accurate and timely alerts, reducing false alarms.

- The absence of sensor loops eliminated common points of failure, increasing the system’s reliability.

Cost Savings:

- Lower maintenance and operational costs due to the durable and efficient design of the Loopless Rip Detection system.

- Long-term cost benefits from reduced downtime and minimal ongoing maintenance requirements.

Estimated Costs Per Belt Rip:

The Loopless Rip Detection System can detect and mitigate belt rips early, significantly reducing associated costs. Based on statistical information, the average costs for a 200-metre-long belt rip are as follows:

- Downtime costs: Approximately AUD 123,000

- Service costs: Approximately AUD 82,000

- Belt costs: Approximately AUD 41,000

While the event cannot be entirely prevented, its impact can be minimised. These figures are averages, and actual costs can vary depending on the specific customer and application. The Rip Prevent System helps significantly lower these costs by preventing extensive damage and reducing downtime.

Positive Client Feedback:

The customer reported high satisfaction with the system’s performance and impact on their operations.

“The Loopless Rip Detection System has drastically improved our operational efficiency. The real-time alerts and rapid response have prevented potential catastrophes, saving us both time and money. We highly recommend this technology for any mining operation.”

The successful implementation showcased the potential of this technology for broader applications in the mining and bulk-handling industries.

Key Benefits:

- Low Investment Costs: The system is cost-effective, with lower initial and ongoing expenses compared to competitor systems.

- Monthly Cost Advantage: The monthly cost is effective because if the system catches only one rip a year, the annual fee is offset by the reduced downtime, enabling repairs that extend the belt’s lifespan and potentially saving significant costs.

- Comprehensive Coverage: All add-ons and functions are included in the monthly fee.

- Lifetime Hardware Warranty: Ensures long-term reliability and cost savings.

- Lifetime Software Updates: Keeps the system up-to-date with the latest technology; this is included in the monthly fee.

- Universal Applicability: Suitable for every belt and conveyor system.

- Optimal for Fabric Belts: Preferably suitable for fabric belts, but suitability for steel cord belts needs to be assessed individually.

- No Inductive Sensor Loops Needed: Eliminates the need for installation and maintenance of sensor loops or rip inserts.

- No Wear Risks: Reduces risks of wear and tear.

- Cost Savings: No costs for sensor loops or rip inserts and their replacement when damaged or faulty.

- Supplier Independence: Independent from belt supplier.

- Versatile Suitability: Suitable for each cover thickness.

- Quick Implementation: Fast implementation (<1 day) and direct monitoring of the conveyor system.

- Unique Functionalities: Offers functions like Rip Detection, Anomaly Detection, and independent mass flow verification from the weightometer.

To learn more about this innovative technology, please get in touch with our engineering team at engineering@rema-tiptop.com.au.

INTERNATIONAL

INTERNATIONAL