REMA Tip Top Australia offers an extensive range of specialised hose manufacturing services from our facility in Bunbury, Western Australia. We cater to the needs of the mining, drilling, water transfer, and industrial sectors, delivering customised, high-quality hose solutions.

Mining Hoses:

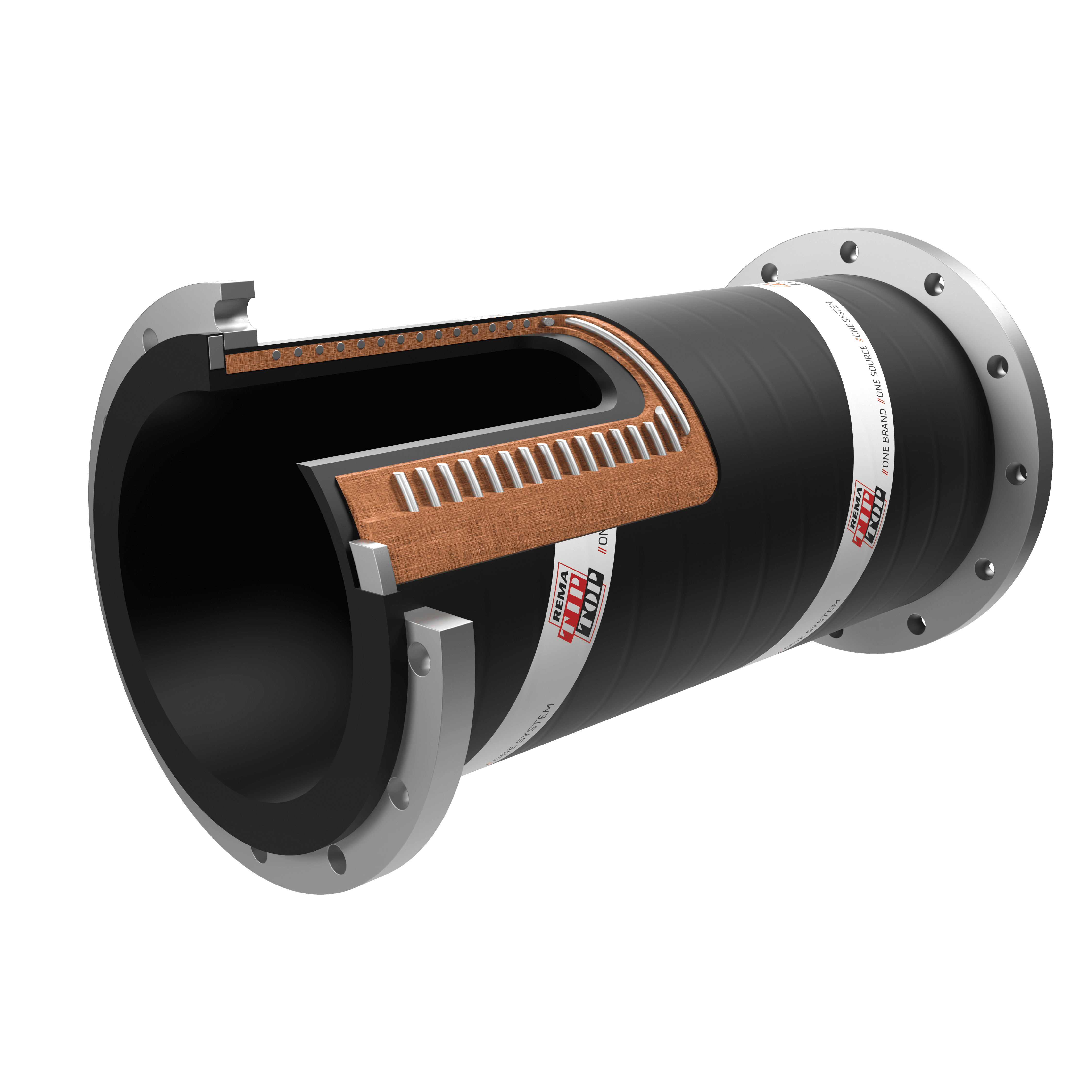

Muff Coupling Hoses:

Rubber Hoses:

At REMA Tip Top Australia, we are committed to ensuring plant reliability and longevity, reducing operational costs, and optimising up-time. We provide:

When selecting a hose, it is crucial to be as informed as possible about its application, the substance it will convey, the operating conditions, and the type of coupling required. Please refer to the checklist below, which includes notes to help you verify the most important points.

The inside diameter of the hose (abbreviated to ID) is generally used when referring to hose size. The inside diameter is important for several reasons, including flow capacity, pressure drop, and choice of coupling.

The overall outside diameter of the hose (abbreviated to OD) is important when selecting couplings or hose clamps.

The total thickness of the hose wall, including the tube, reinforcement, and cover.

The maximum working pressure is the level for which the hose is designed and may be subjected to.

The pressure at which a new hose will burst or otherwise fail.

The minimum radius to which the hose can be safely bent.

This refers to the length of the hose supplied. For coupled hoses, it is the length from one coupling end to the other.

The substances that will be conveyed by the hose are crucial. The temperature, concentration, and composition of these substances may be important.

The type of coupling that is to be fitted onto or permanently vulcanised to the hose requires specification. This includes information on the type of thread, flange specifications, etc.

Reference to any applicable standards, production certificates, or other design regulations.

The environment in which the hose will be used is crucial, including external temperature, exposure to oil, and contact with abrasive materials such as floors and stones.

Markings, such as the working pressure, the company name, and the substances carried, may be applied through printing, embossing, or labels.

Various additional pieces of information, such as the method of packaging, delivery, or other special requirements, may be specified.

"*" indicates required fields