CASE STUDY : REMATRACK BELT TRACKING

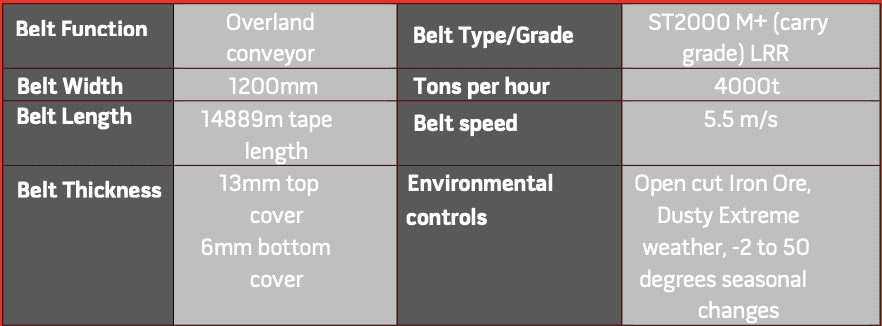

Location: Western Australia, Industry: Iron Ore, Solution: REMATRACK FTX, REMATRACK TTX.

A major mining organization was having regular belt tracking issues with its overland conveyor resulting in regular hours of production loss and downtime. Downtime was due to belt tracking issues caused by multiple splices on the belt not being square, and earth movement to the structure over time.

ISSUE ON SITE:

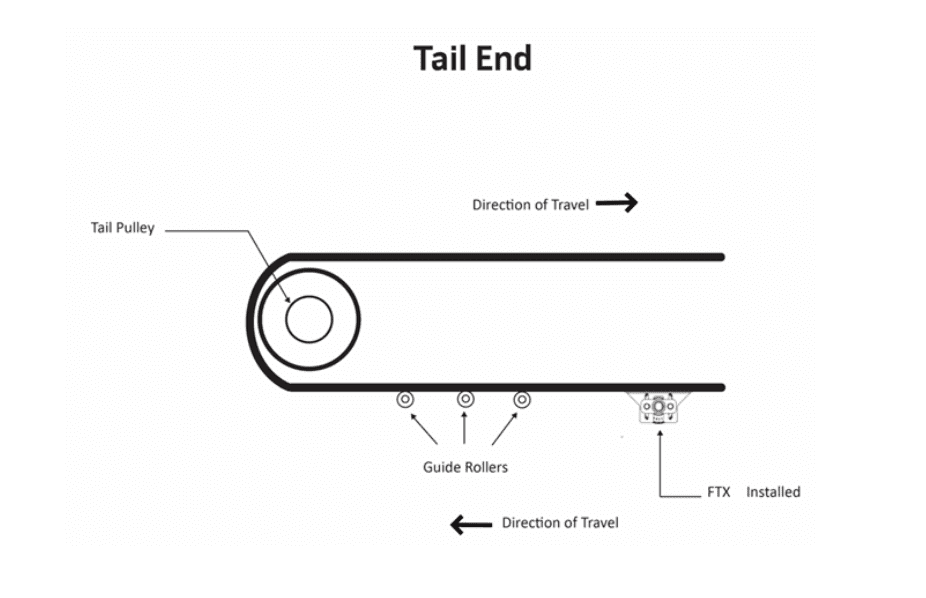

It was evident tracking was at its worst at the tail end due to witness shine marks on the guide rollers and clear left to right belt movement across the pulley while the belt was in service.

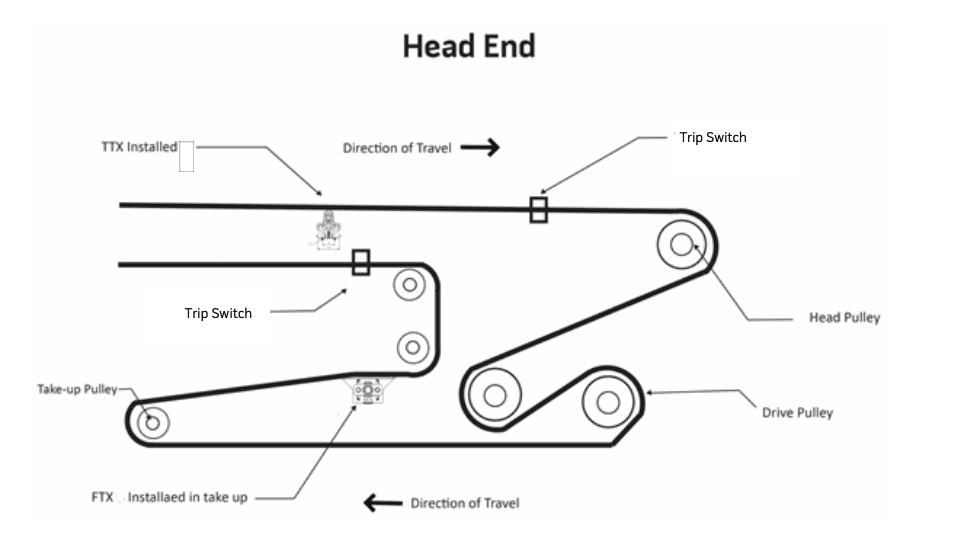

The other issue was the trip switches at the head end. Regular down time was occurring from the belt tracking off and contacting the switches that will instantly stop the conveyor for safety. This would then require a shift electrician to find the trip and physically go to the location to do a reset before the conveyor can start again. This issue had become gradually worse after the installation of a new belt 2 years ago with trips occurring at any time of day or night.

Areas for immediate attention were identified as:

- Tail pulley area with belt tracking hard into guide rollers prior to pulley with constant movement left to right across the pulley as belt travels.

- Head area trip switches with belt tracking left to right contacting the switches causing automatic system stoppage.

Example of shine marks on guide rollers from constant belt tracking contact.

THE SOLUTION :

2x REMATRACK FTX (flat return trackers) and 1x REMATRACK TTX (dynamic trough tracker) were recommended as a solution and trailed. See diagrams for locations.

These tracking units are ideal for heavy duty dusty environments. The tapered polyurethane lagged rollers are perfect for automatically correcting belt drift and offer extended service life through heavy duty bearing configurations, high quality lagging and REMA super seal design.

Currently after 6 months in service downtime across the whole system is down by 65% and no trip issues have occurred at REMATRACK targeted areas.

The Trail has been labeled a success and REMATRACK is being scoped for other installations to support tracking issues on site.

INTERNATIONAL

INTERNATIONAL