CASE STUDY: BELT MISALIGNMENT AND CARRYBACK ISSUES

A major mining organisation in Central QLD was experiencing regular belt tracking issues with its overland conveyor, leading to significant production loss and downtime. The belt tracking problems were caused by multiple splices not being square and structural movement over time.

CHALLENGES:

- Belt Tracking Issues: The overland conveyor faced frequent tracking problems, resulting in production loss and downtime.

- Heavy Carryback: The conveyor also suffered from heavy carryback, leading to unexpected shutdowns.

SOLUTION:

REMA TIP TOP introduced a tailored solution by installing:

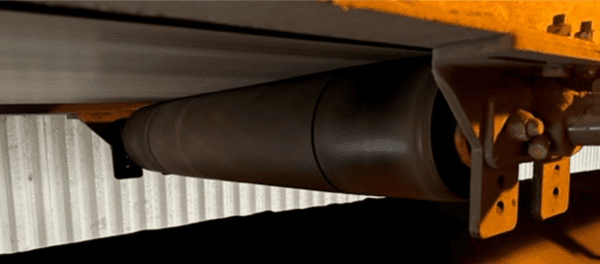

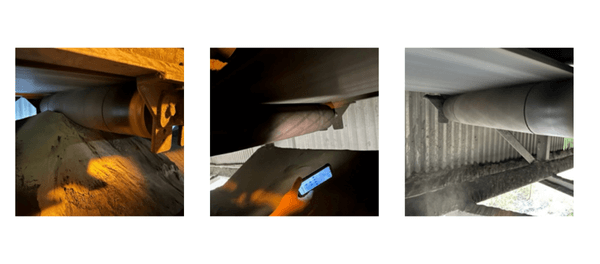

- 3 REMATRACK FTX 750 HDP units: Positioned at 1, 2, and 3 along the conveyor.

THE RESULTS:

The installation of the 3 REMATRACK FTX 750 HDP units has yielded remarkable improvements:

- Enhanced Performance: After 9 months of service, the REMATRACK units are performing exceptionally well with no tracking issues. The super seal of REMATRACK effectively protects its internal components under serious carryback conditions.

- Increased Productivity and Reliability: The conveyor’s productivity and reliability have significantly improved, with the customer reporting satisfaction as the issues no longer exist. The design of REMATRACK without guide rollers eliminates the risk of belt edge damage.

The REMATRACK units are expected to continue operating effectively for another 9 months or longer, underscoring the durability and efficiency of REMA TIP TOP’s solution.

Discover more about our belt tracking solutions here.

INTERNATIONAL

INTERNATIONAL