Automated Roller Failure Detection & Monitoring

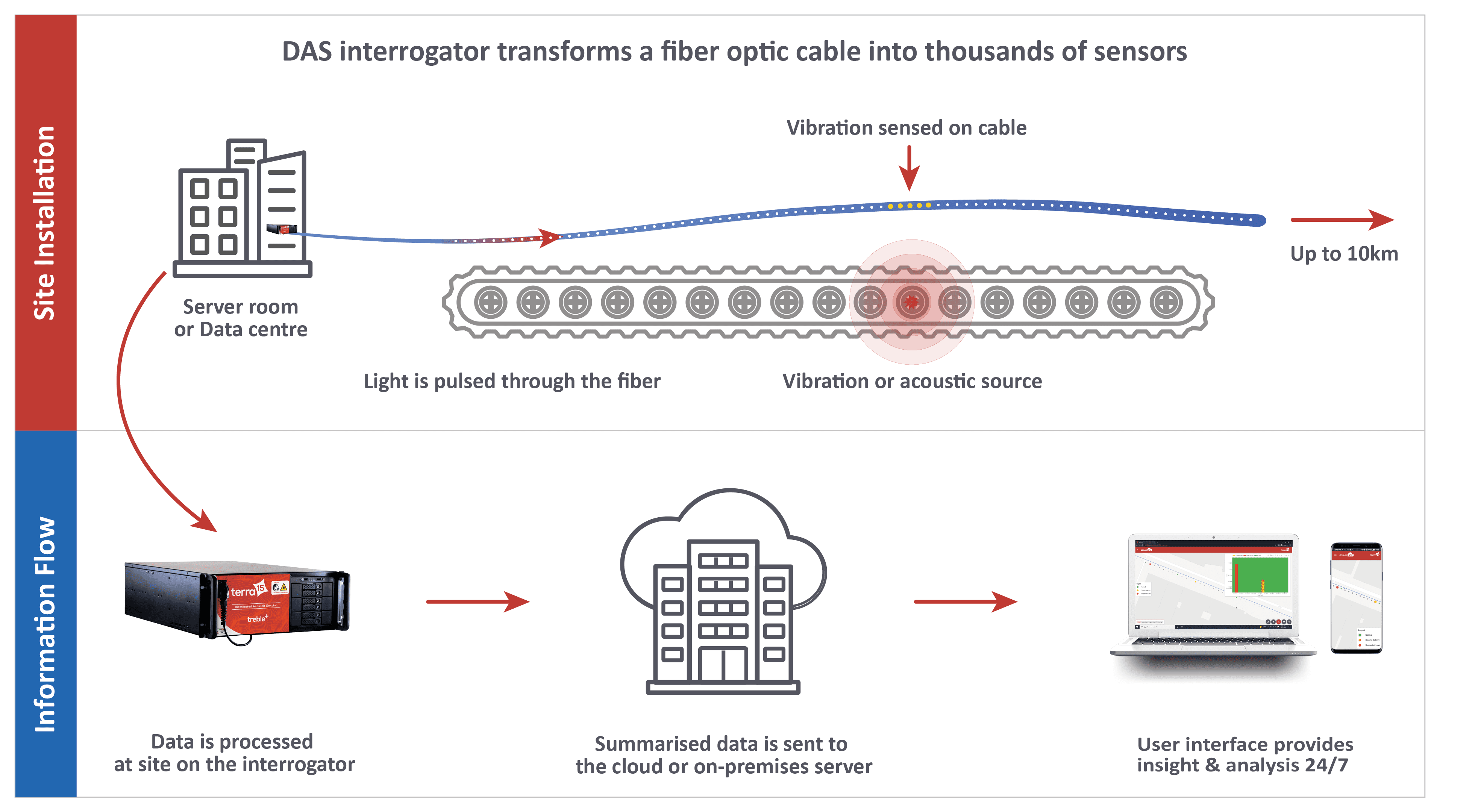

Our advanced Distributed Fiber Optic Sensing (DFOS) solution offers complete, real-time monitoring of your conveyor systems. By detecting early-stage failures and delivering continuous data insights, you can reduce downtime, improve operational safety, and increase productivity—all while minimising the need for manual inspections.

INTERNATIONAL

INTERNATIONAL