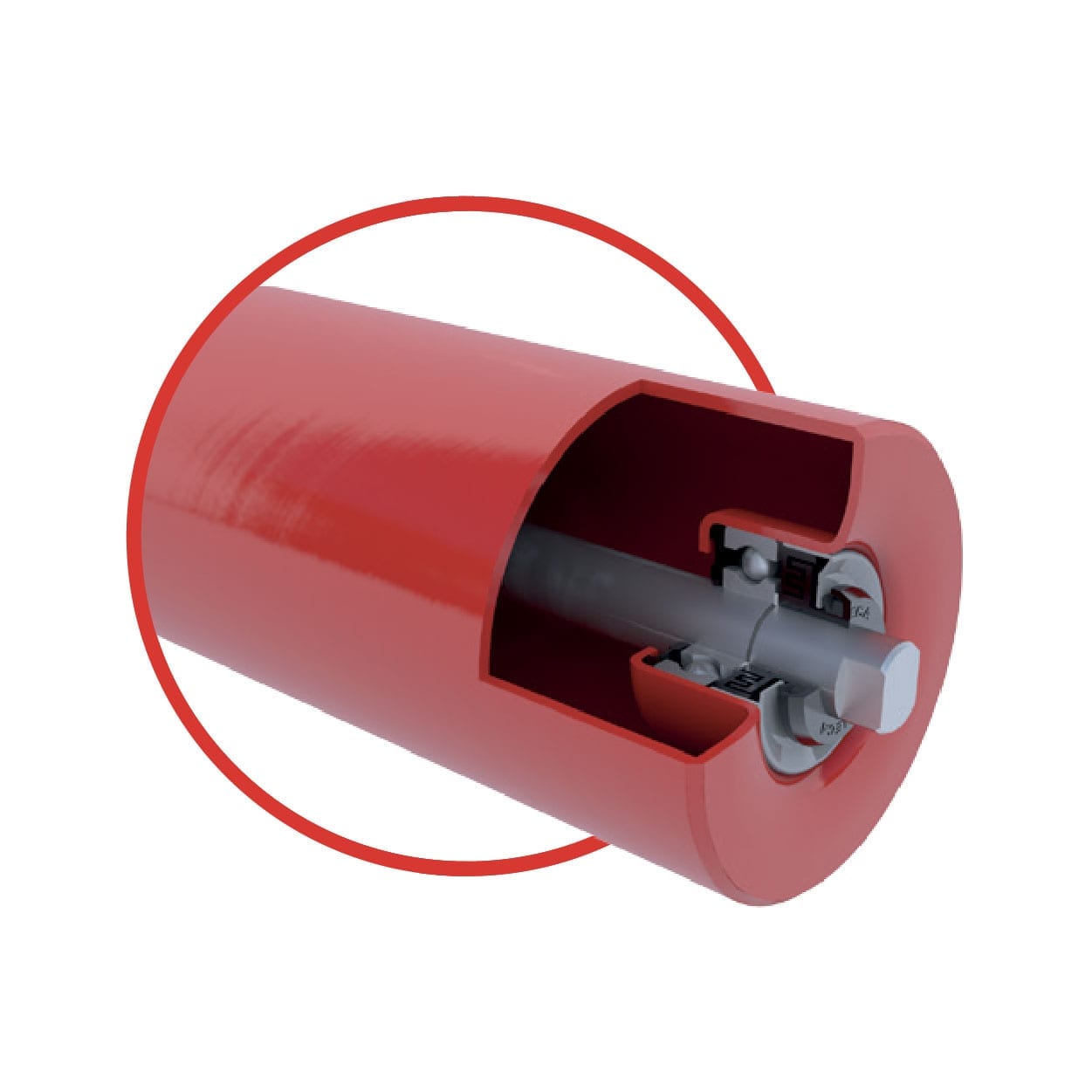

Totally enclosed

The motor, gearbox and bearings are totally enclosed and sealed inside a steel shell; therefore they are unlikely to fail due to harmful environmental conditions such as water, dust, grit chemicals, grease, oil, etc.

Space saving design

Because the drive unit and the bearings are mounted inside the Motorised Pulley shell, it takes up much less room than a conventional drive. No need for costly extras like chains, v-belts, couplings, bearings, support structure and special guarding.

Safety

Our Motorised Pulley is probably one of the safest drives available because the motor is completely enclosed and the external shafts are always stationary. The only moving external parts are the Motorized Pulley shell and bearing housings.

Low purchasing and installation cost

Our Motorised Pulley is quite often less expensive than exposed drives because it has fewer parts. Therefore less conveyor design and parts purchasing costs. It is also much quicker and easier to install – certainly less than a quarter of the time taken to fit an exposed system.

Low maintenance cost

The end user also benefits from our Motorised Pulley, because it requires no maintenance other than the recommended oil change every 20,000 hours and oil seal change every 30,000 hours. In other words almost 10 years between oil changes based on an 8-hour/ day working week. Synthetic oil can be specified to extend the service range up to 50,000 hours.

INTERNATIONAL

INTERNATIONAL