MCube Belt Thickness Monitoring (BTM)

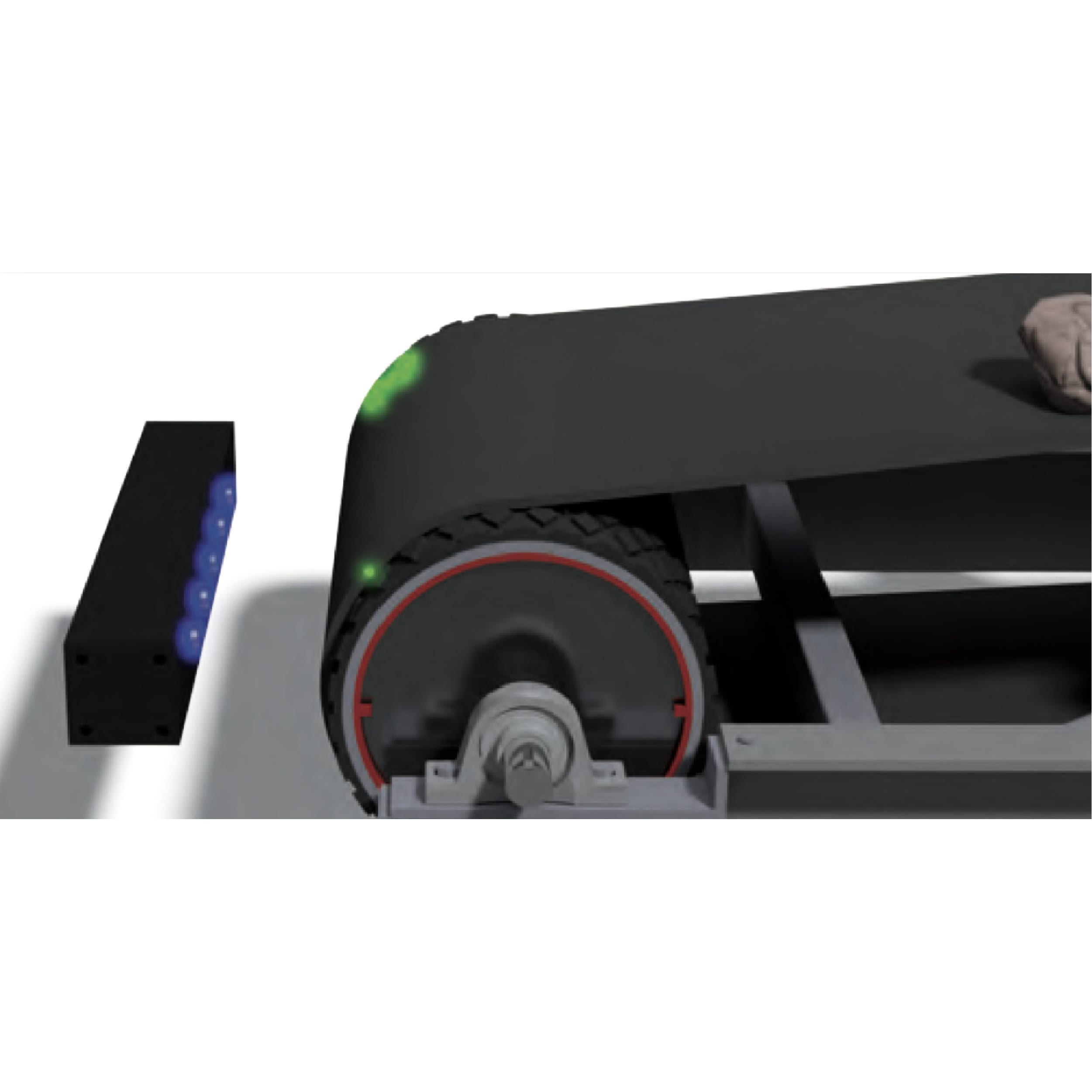

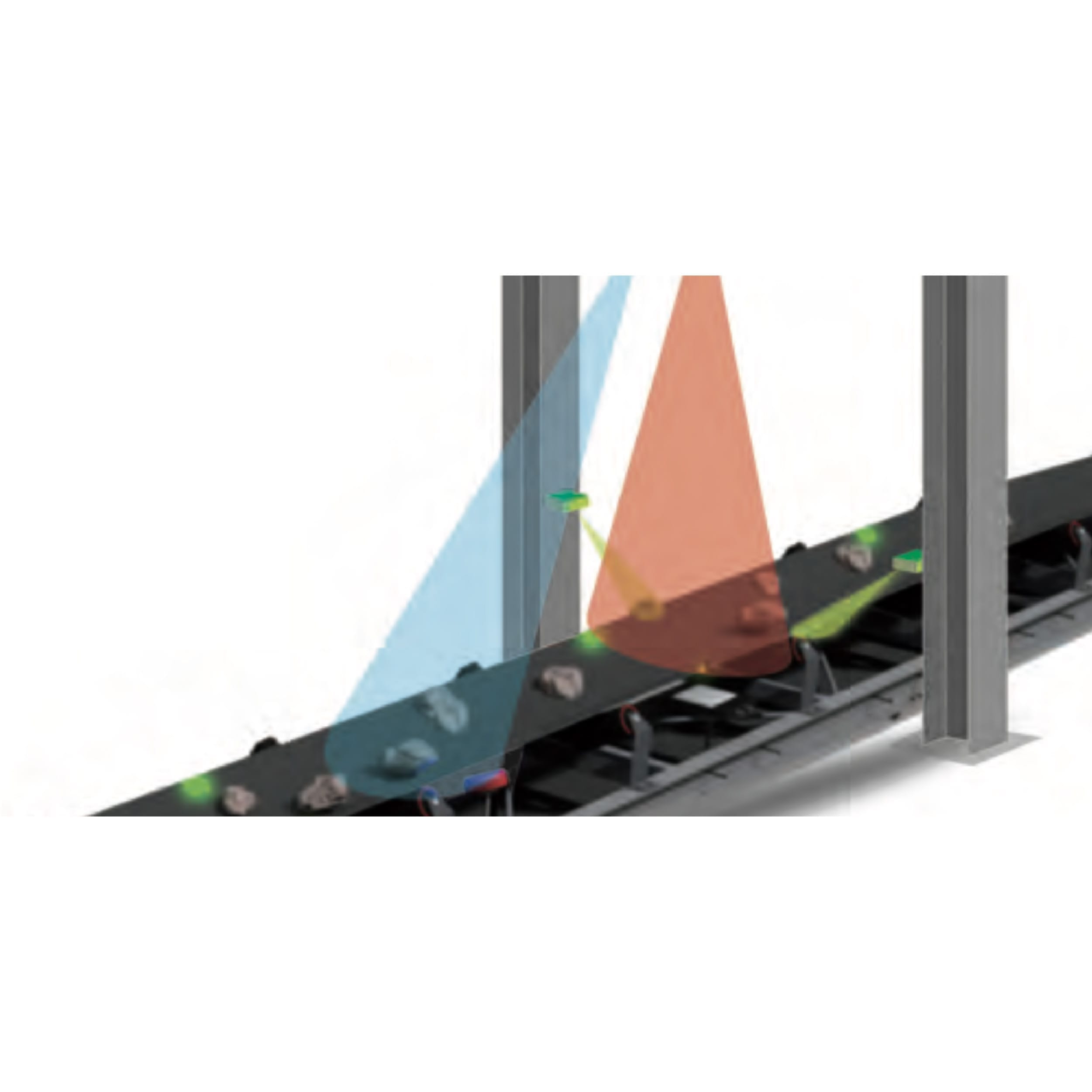

One of the most important factors is an increased life expectancy of conveyor belts. The Belt Thickness Monitoring System (BTM) continuously measures wear and wear characteristics on conveyor belts by use of ultrasonic sound-waves, these sensors generate over 1.000 readings per second in order to present an accurate graphical representation on the clients belts. The system makes use of a RFID tag which allows our software to pinpoint any damage on the belt, then it compares the damaged area to historical data and calculates when this damaged area will become critical.

INTERNATIONAL

INTERNATIONAL